Bagru printing is one of the traditional techniques of printing with natural colour followed by the chippas of a remote place of Rajasthan. The process starts from preparing the cloth to finished printed fabrics through their indigenous methods. Motifs having some specialty are transferred onto light coloured background with wooden blocks following two styles direct and resist style. Although this technique is facing problems against the threat of globalization, this exotic art of creation is required to be encouraged in the present context of environmental consciousness.

Introduction:

Indians were among the pioneers in the art of dyeing and printing with fast (natural) colour in the world. Dyeing with indigo was more of a mystery to many foreign travelers to India because they could observe no colour when fabric is dipped in indigo bath colours develop during exposure in open air1. Hand block printing has been recognized as a craft through generations in different clusters in the country. Each cluster follows its distinctive style & methods, uses locally available natural materials and motifs of some specialty. ‘Bagru’ print is that kind of centuries old traditional art of hand block printing still alive

STEP 1: WASHING

This step is important to rid the fabric of any impurities. In the olden days, they would use cow dung diluted in water to do this. My fabric was already treated so I began on the second step.

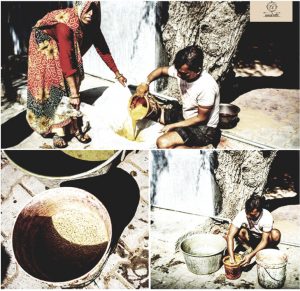

STEP 2: HARDA DYEING

The fabric is dyed in cool water and harda powder. Think of this as a primer. Without this step, the dye will not absorb into the cotton properly.

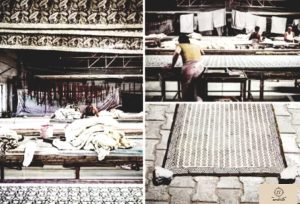

STEP 3: DRYING

Once dyed, the fabric needs to lay flat and dry in the sunlight. The fabric will have a yellowish tint after this stage, which will later disappear once washed.

Next we are showed just how important this step is. Fabric that has and hasn’t been treated with harda is dipped into black dye and you can see the difference. The untreated fabric is the white fabric on the left, and the harda treated fabric is the yellow tinted fabric on the right.

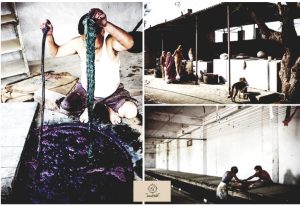

While the fabric is drying, we watch as colors are mixed.

Just how these color recipes were made still blows me away. The method for black especially boggles my mind. These are the colors used today…

Black: Horseshoes that sit on coals for a period of time, brushed of rust are then put in cans with water and sugar cane juice, left to ferment for periods of months to yield black dye.

Red: A mixture of natural gum paste and alum.

Brown: Red kashish with water.

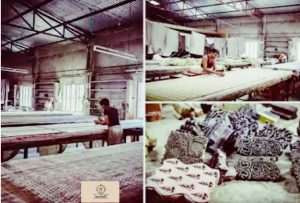

We also had a little time to peek around the factory…

The guys here do it so effortlessly, some masters have been block printing for more than 30 years. I’m about to find out how it’s not as easy as it looks. My fabrics are now ready, dry and primed for…

STEP 4: PRINTING!

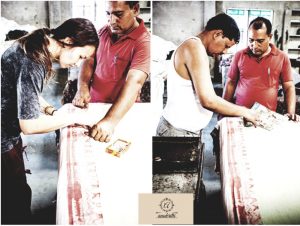

I first stretch and pin the fabric onto the printing table and choose some blocks for my design. A master helps me start my border corners…

I find out quickly this takes precision. The block is placed from left to right and then slammed hard with your fist on the back of the handle for complete registration.

I finish the border and it’s time to print with my outline block for my main zig-zag pattern.

Now time to fill those zig-zags. I choose red, which appears yellow at this point. It won’t show as red until the last step when it is boiled with the presence of alizarin (root of Indian Madder Tree). Now I use the filling block, which is like the inverse of the outline block. This is getting tricky!

I also print the border with brown dye and proceed to…

STEP 5: DRYING

Now that I’ve practiced with one, I move on to scarf number two!

This time I opt for a monochromatic geometric pattern using only black ink. Here we go! I’m also guided by a few other printers that help me with the print.

My hands at this point are sore from slamming the blocks, but my print is done and I am loving it. Time to lay it out to dry!

We break for lunch while they dry, and are showed the indigo dyeing pot and another part of the factory where they silk screen.

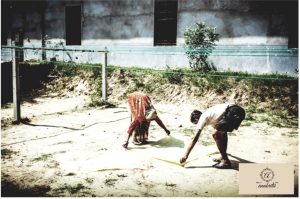

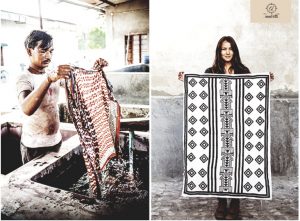

STEP 6: WASHING

The fabric is now ready to be washed in cool water.

The pieces are beaten against the concrete and ready for the final step…

STEP 7: BOILING

This is where the color fasting takes place with the help of flowers from the Dhaura tree. Pieces with red dye is boiled in a separate pot with alizarin which then turns the once yellowish color red.

Once boiled, they give it a quick rinse, quick spin to dry and they are done. They dry in the sun and I have two scarves that I’m ready to rock.

A few days pass and the bruises are still visible on my hands.

Beauty is pain.